Board-to-board connectors are fundamental components in electronic assemblies, facilitating the interconnection of multiple printed circuit boards (PCBs) within various devices. These connectors play a critical role in enabling data transfer, power distribution, and signal routing between PCBs, making them essential in diverse industries ranging from consumer electronics to aerospace.

Board-to-board connectors, also known as interconnects, are devices used to establish electrical and mechanical connections between two or more PCBs. These connectors typically consist of male headers (pins) on one PCB mating with female receptacles (sockets) on another PCB. The primary function of board-to-board connectors is to ensure reliable transmission of signals, power, and data between interconnected circuit boards.

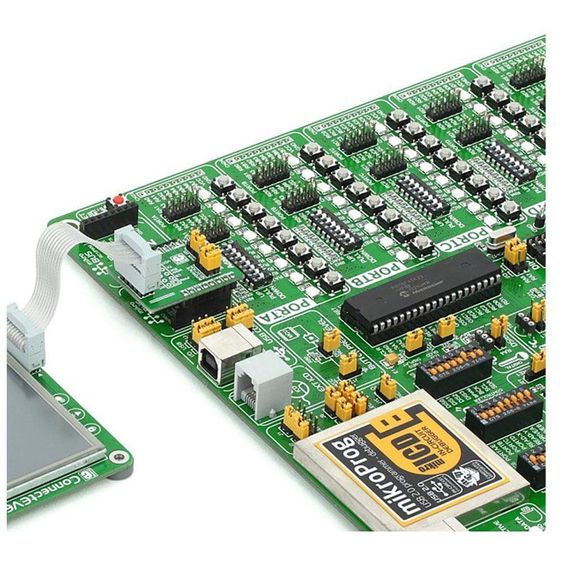

These connectors have pins that pass through holes in the PCB for soldering, providing robust mechanical stability. Through-hole connectors are commonly used in applications requiring strong mechanical bonding, such as industrial equipment.

Designed for automated assembly, surface-mount connectors attach directly to the surface of PCBs without the need for through-holes. They are preferred for compact and lightweight electronic devices like smartphones and tablets.

Mezzanine connectors enable perpendicular mating between stacked PCBs, allowing for space-efficient designs in applications like servers and networking equipment.

Edge connectors are located along the edge of PCBs and enable horizontal mating between boards. They are widely used in computer systems and peripherals.

Pitch and Size: The pitch (distance between pins or sockets) and overall size of the connector are crucial considerations, especially in compact electronic designs where space is limited.

Signal Integrity: High-speed applications require connectors that maintain signal integrity by minimizing signal loss and electromagnetic interference (EMI).

Current Rating and Voltage: Ensure that the connector can handle the required current and voltage levels to prevent overheating or electrical failures.

Durability and Reliability: Choose connectors with adequate durability for the intended application, considering factors such as mating cycles, environmental conditions, and mechanical stress.

Board-to-board connectors find applications across various industries and electronic devices, including:

Consumer Electronics: Smartphones, laptops, gaming consoles, and wearable devices utilize board-to-board connectors for compact and reliable internal connections.

Automotive Electronics: In-vehicle infotainment systems, engine control units (ECUs), and advanced driver-assistance systems (ADAS) rely on board-to-board connectors for robust connectivity in demanding automotive environments.

Industrial Equipment: Factory automation, robotics, and control systems use board-to-board connectors for interconnecting PCBs in rugged industrial environments.

Telecommunications: Networking equipment, routers, and switches employ board-to-board connectors to ensure high-speed data transmission and reliability in telecommunications infrastructure.

The evolution of board-to-board connectors is driven by ongoing technological advancements, including:

Miniaturization: Smaller and more compact connectors enable the development of thinner and lighter electronic devices.

High-Speed Data Transmission: Advanced connectors capable of supporting higher data rates are essential for emerging technologies like 5G and IoT.

Integration with Flexible Circuits: The integration of flexible circuitry with board-to-board connectors enables greater design flexibility and durability in portable electronics.

In summary, board-to-board connectors are essential components in modern electronics, allowing for efficient and reliable connecting between PCBs in a variety of applications. As electronic systems shrink in size and performance, board-to-board connectors play an increasingly important role in allowing communication and functionality. Understanding the many types, applications, and concerns for board-to-board connections is critical for electrical designers and engineers looking to improve the performance and reliability of their devices.