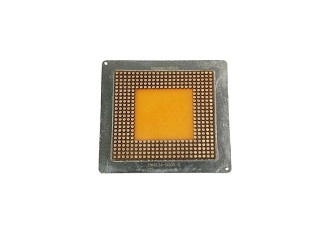

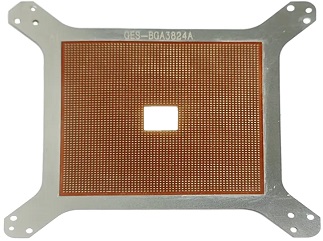

PCB Test Elastomer, often made of silicone rubber, is a versatile material used in various applications such as electronic device assembly, vibration dampening, and sealing. Its elastic properties allow for conformal contact in fine pitch applications, making it ideal for use in fine pitch test sockets and as a contact interface in electronic testing and packaging.

Durable and Consistent Contact

Excellent Electrical Impedance(<100mΩ)

Fine Pitch(0.075mm)

Easy to Replace

Made in large sheets,can be cut to the required size.

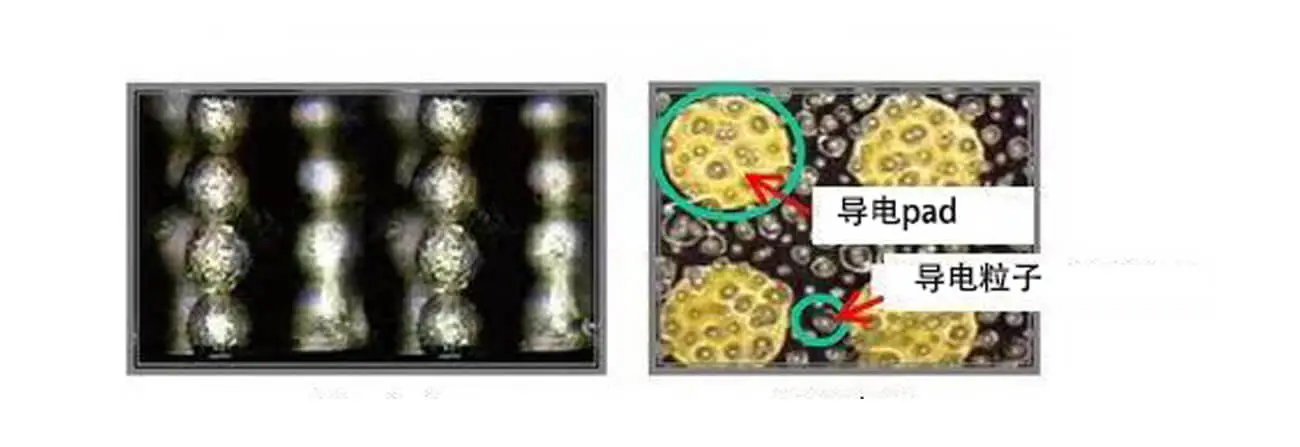

Electronics Testing: The PCB test elastomeric film acts as a compliant interface in elastomer sockets for ensuring reliable electrical contact between test probes and semiconductor devices.

Flexible Electronics: The PCB test elastomeric film enables the creation of flexible electronic circuits and displays by serving as a substrate or encapsulation material.

Energy Harvesting: The PCB test elastomeric film can be used in energy harvesting devices to convert mechanical motion or vibration into electrical energy due to its elastomeric properties.

Enhanced Electrical Properties: Development of elastomeric films with improved electrical conductivity enables their use in emerging applications such as flexible electronics, stretchable circuits, and wearable sensors.

Tailored Mechanical Properties: Advancements in material science have led to elastomer films with customizable mechanical properties, including stiffness, elasticity, and damping characteristics, allowing for optimized performance in specific applications such as vibration isolation and shock absorption.

Integration with Nanotechnology: Integration of nanomaterials such as carbon nanotubes, graphene, and nanocomposites into elastomer films enhances their mechanical strength, electrical conductivity, and thermal properties, enabling new functionalities and applications in areas such as energy harvesting, sensing, and actuation.